Elettrondata helps you achieve top-quality production and high business efficiency using innovative technologies and experiences proven in more than 7,000 plants globally.

Integrated Automation Solutions Customized to Concrete Producers’ and Plant Manufacturers’ Needs

With expertise built from meeting the demanding product constraints in multiple industries, Elettrondata is ready to provide your facilities with the highest-quality automation software in the industry.

Ready-Mix Production

With more than 40 years of experience in RMC automation, see how our solutions can increase your customer loyalty

Precast Production

The precast concrete industry has demanding requirements that our solutions solve in every plant you have.

Asphalt Production

Coordinating and delivering products that meet the demanding needs of asphalt construction is part of our DNA

Other Industries

Elettrondata provides automation in a variety of mixture-based production facilities, including food,

READ MORE

MODERNIZE INTELLIGENTLY TO ACHIEVE 24/7 PRODUCTION

The Most Comprehensive Hardware & Software Automation Solutions for the Concrete Industry

Producing an accurate mix to precise specifications is critical to building the long-lasting relationships that ensure the business success of ready-mix producers. Concrete producers leverage automation of production to ensure their plants manufacture precise loads every time.

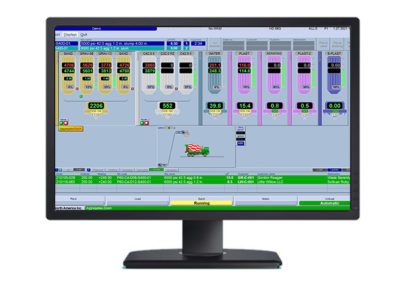

Elettrondata’s eBATCH Ready Mix, eBATCH Precast, and eBATCH Asphalt are robust automation system for ready mix concrete systems, precast concrete sites, and asphalt plants that allow them to provide to-specification mixes that build customer confidence and loyalty. These highly configurable software systems provide facilities with the ability to produce any variety of concrete or asphalt products without delays incurred when production stops to change mixes.

Efficient. Accurate. Reliable.

Ready mix concrete producers who manage multiple plants in an area need the ability to optimize their operations so that all orders are delivered with accuracy on time. The ability to track resources, manage raw materials, and schedule production across their multiple plants is not simple.

Elettrondata’s eDISPATCH provides real-time on-the-spot status of every vehicle and load for every customer across all production facilities. The solution tracks the status of all orders, materials at the facilities, and utilization of all fleet and facility resources to manage the production and delivery of to-specification mixes to every customer site on time.

Accurate. Timely. Dependable.

Producing accurate mixes to precise specifications is critical to building loyal relationships for ready-mix producers. Using research, experience, and commitment, concrete producers incorporate automation to ensure and prove that their plants create precise loads.

Elettrondata’s eQUALITY Assurance creates and retrieves concrete mixes to ensure predictable reliability of concrete. Elettrondata’s eQUALITY Control stores, tracks, and provides access to specimen testing results of mixes, and Elettrondata’s eSLUMP is the most accurate on-truck tracking system that ensures concrete delivered to a site meets the customer’s workability needs, by measuring slump and tracking adjustments made on site. These systems help concrete producers prove the reliability and performance of their concrete products.

Accurate. Reliable. Simple.

Automating production is only as accurate as the inputs that the line equipment provides. High-quality, robust sensors are paramount for measuring and communicating the composition of the raw materials being mixed into the products.

Elettrondata’s ePROBE is a rugged high-quality sensor for detecting moisture in sands moving on a conveyor belt or passing through extraction gates. Elettrondata’s eWEIGHERS are highly precise instruments that provide real-time weight measurements from any line of raw materials to the mix-control system. By knowing the accurate moisture content and weight of materials, the system knows the precise amounts of water or ice to add to the mix to ensure to-spec concrete.

Accurate. Durable. Reliable.

Upgrade Plants without Stopping Production

Elettrondata provides complete migration solutions that transform legacy, out-of-date manufacturing methods to efficient, modern production systems.

The low-cost eConvert system connects your existing plant production facilities to today’s state-of-the-art automation control.

CHECK OUT OUR WORK

Our Impact

We provide significant impact to the operational successes of our customers and our partners!

7000 +

Plants Automated Globally

# 1

Achieved the best Rating on Slump Accuracy Measurement

3500 +

Measuring and reporting slump on mixers

96 +

Hours of Non-Stop Production Demonstrated

45 +

Years in Concrete Industry

5

Patents on technology that improves plant operations

Testimonials

Elettrondata’s innovative eBATCH RM is our go-to automation product. eBATCH flexibility allows us to deploy this software in 100 of our plants to optimize our concrete production.

We expected automation would help our production, and Elettrondata’s eBATCH Precast automation system increased our concrete production by 25%.

Elettrondata’s eBATCH Precast provides our plants with unmatched flexibility in our precast production sites. We have the ability to change admixtures and aggregates at any time, which provides us with unmatched production agility and efficiency to meet our customer demands

Elettrondata’s innovative eBATCH RM is our go-to automation product. eBATCH flexibility allows us to deploy this software in 100 of our plants to optimize our concrete production.

The growth in our market demands that we operate efficiently and consistently day and night. The unique flexibility of Elettrondata’s solution allows us to synchronize and optimize our production of orders without the need to halt production to change the mix.

Axiontek

Acquarius

Unical

Mapei

J&R PRECAST

Kerakoll