Efficient and Automated Control of Concrete Specimen Management

The access to information regarding the testing of concrete quality is paramount for concrete manufacturers, project managers, general contractors, and laboratory officials. Creating digital records eliminates paper records and human errors and increases the reliability of the information about specimens.

eQUALITY Control Provides Reliable and Accurate Reporting of Concrete Testing Results

eQUALITY Control allows fast and efficient storage of specimen information before, during and after testing. The system provides direct and confident access to the correct specimens during acceptance testing phase, along with easy, secure access to those persons providing test results for specimens.

Improved Internal Controls

Accurate, Transparent Traceability

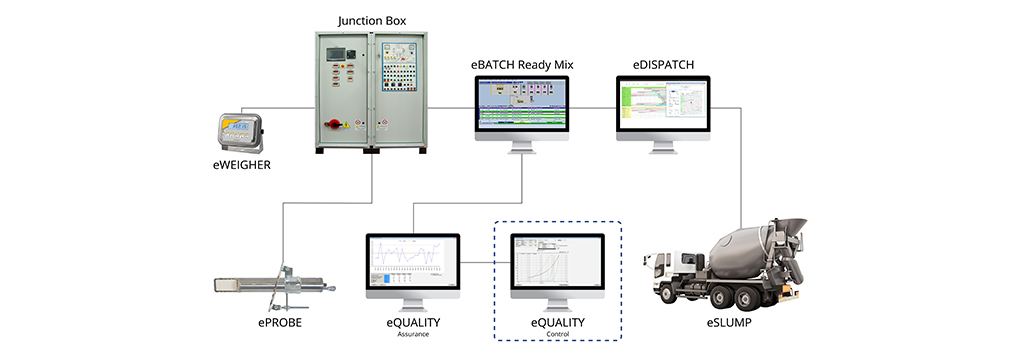

Elettrondata’s End-to-End Automation System

Key Features

- Secure on-demand access – eQUALITY Control provides anytime access to specimen data and test results stored on the Quality Control server and accessed by the Quality Assurance client on a laptop or PC.

- RFID-based specimen Tags – eQUALITY Control provides support of both UHF and LF tags to allow either reusable or disposable specimen tracking devices, respectively.

- Affirms adherence to process – eQUALITY Control automatically establishes testing deadlines for the number of tests for new specimen entry.

- Simplifies resource scheduling – Deadlines are exportable to IT-supported calendars like Outlook to generate appointments for scheduling of resources.

Our Differentiators

- Secure direct access to specimen information from the field using client.

- Variety of security levels controls access to information about the specimen.

Operating in 7000+ Plants

Demonstrated Non-Stop Production for 96 Hours

Tailorable to any configuration

RELATED PRODUCTS

FAQ's

No. eQUALITY Control operates using standard IP network communications with other servers and computer equipment configured to operate on a LAN or Internet connection.

Yes. In addition to the eQUALITY Control Server and Clients, the eQUALITY Control solution also uses a series of hardware sensors and identification tags along with components like RFID reading terminals, label printing equipment and RFID tags and rewritable badges. Depending on your operations, eQUALITY Control will need IP network access for external parties like testing facilities to access the server for providing test results.