Efficient Multi-plant RMC Delivery Management system

RMC producers managing multi-site RMC operations need to optimize their delivery processes to efficiently meet the on-time needs of all customers. The ability to track resources, manage raw materials, and schedule production is not simple.

eDISPATCH Centralizes RMC Deliveries For Every Plant

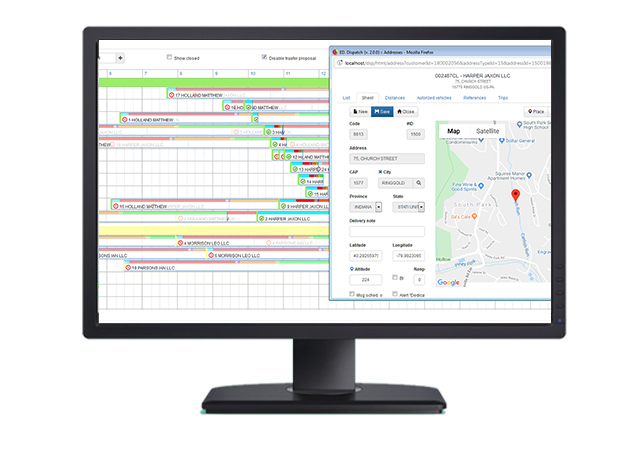

eDISPATCH provides real-time on-the-spot status of every load for every customer and manages orders, trips, and fleet and facility resources across all plant facilities to deliver high-quality mixes to customer sites on time to build customer loyalty.

Predictable non-stop 24x7 operations

Intuitive and Easy To Use

On time Delivery Every Time

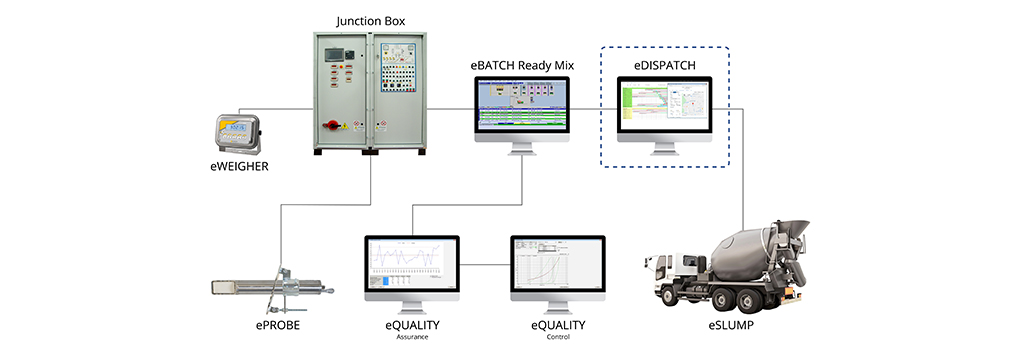

Elettrondata’s End-to-End Automation System

Key Features

• Continuous real-time information – eDISPATCH receives up-to-the-second information from end-to-end resources to adjust scheduling to meet load delivery commitments

• High-tech optimized software – the on-premise or cloud-based solution provides advanced and optimal resource planning, including location and status of vehicle

• Integrated easy-to-see status – real-time visualization on area map of statuses of all plants, trucks, and delivery sites

• Easy-to-understand reports – Production chart and status reports for order/delivery/return status by plant and vehicle

Our Differentiators

• Flexible deployment options – Simple, flexible, and highly scalable system, located on-premise or cloud-based

• High industry experience – 20-years of concrete dispatch expertise

• On-/off-line operations with auto-synchronization – Integrates estimates, orders, credit checks and invoices in a single solution

Operating in 7000+ Plants

Demonstrated Non-Stop Production for 96 Hours

Tailorable to any configuration

RELATED PRODUCTS

FAQ's

No. eDISPATCH can connect to any batch control systems, but eDISPATCH may have reduced capabilities depending on the data provided by the other batch control systems.

No, eDISPATCH can connect to the existing fleet management system, but may have reduced functionality due to the scope of data sent from the other system.

eDISPATCH’s field-proven algorithm provides optimal resource scheduling based on a variety of factors that include plant status and materials, plant utilization, delivery status per truck, truck location, and truck availability. While eDISPATCH provides optimized scheduling, an operator has full control and can adjust scheduling with a simple click of the mouse.