The Industry's Most Comprehensive Asphalt Automation Solutions

With more than 40 years of industrial automation experience, Elettrondata delivers automation for asphalt plants that maximizes plant production and optimizes raw material consumption using ultra-reliable software and in-house manufactured hardware components.

THE ASPHALT AUTOMATION SOLUTION SUITE THAT DELIVERS TOP QUALITY ASPHALT EVERY TIME

Elettrondata’s automation platform for asphalt plants provides manufacturers with high-quality asphalt that creates top quality surfaces.

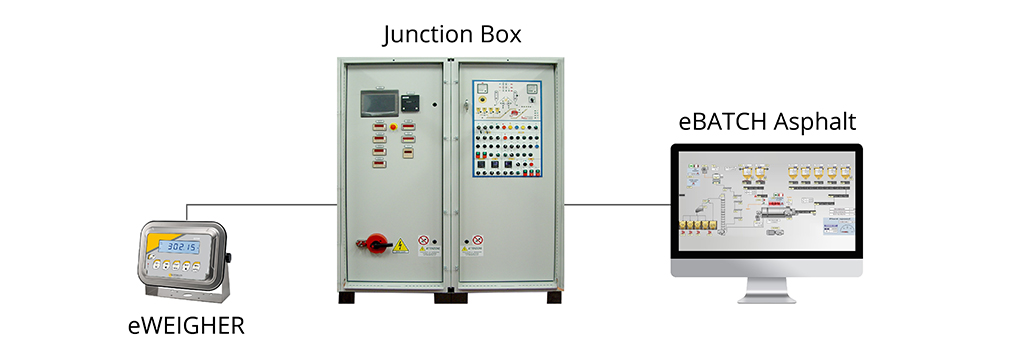

The flexibility, efficiency and reliability of Elettrondata’s eBATCH automation portfolio gives asphalt plants the end-to-end production capabilities that continuously deliver the high-quality asphalt needed to meet their critical daily production milestones.

ELETTRONDATA PRODUCTS TO AUTOMATE

PRODUCTION AND DELIVERY

Testimonials

Elettrondata’s innovative eBATCH RM is our go-to automation product. eBATCH flexibility allows us to deploy this software in 100 of our plants to optimize our concrete production.

We expected automation would help our production, and Elettrondata’s eBATCH Precast automation system increased our concrete production by 25%.

Elettrondata’s eBATCH Precast provides our plants with unmatched flexibility in our precast production sites. We have the ability to change admixtures and aggregates at any time, which provides us with unmatched production agility and efficiency to meet our customer demands

Elettrondata’s innovative eBATCH RM is our go-to automation product. eBATCH flexibility allows us to deploy this software in 100 of our plants to optimize our concrete production.

The growth in our market demands that we operate efficiently and consistently day and night. The unique flexibility of Elettrondata’s solution allows us to synchronize and optimize our production of orders without the need to halt production to change the mix.