The Modern Foundation of Today's Precast Automation System

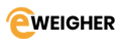

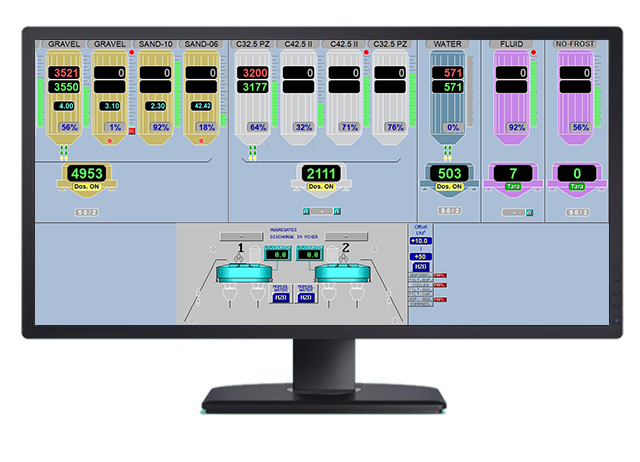

Concrete producers need a system that can accurately and repeatedly produce the exact specifications. Elettrondata’s eBATCH automation system is that solution. eBATCH receives real-time measurements of all raw materials and adjusts the flow of each component during the mixing process.

eBATCH Precast Delivers High Quality

The system’s precision processing makes it the go-to automation platform for precast plants. Elettrondata’s robust automation system delivers accurate-to-specification concrete for delivering the high-quality products that build customer confidence and loyalty.

Predictable non-stop 24x7 operations

High Quality Precision

On time Delivery Every Time

Elettrondata’s End-to-End Automation System

Key Features

- Realtime constant measurement of moisture in aggregates – knowledge of water content is crucial to concrete quality

- Detection and tracking of raw material consumption – facilitates automated traceability reports for compliance testing

- Flexible configurations – ability to configure different tolerance levels increases operational efficiency

- Common software for precast and ready-mix for easy usability and education

Our Differentiators

- Unlimited inventory of mixes

- Automated and customizable quality reports

- AI-based drop control with manual override

- Centrally managed automatic software updates

- Single point of contact for software and hardware components

Operating in 7000+ Plants

Demonstrated Non-Stop Production for 96 Hours

Tailorable to any configuration

RELATED PRODUCTS

FAQ's

No, eBATCH supports interfaces to ERP and fleet management systems.

Yes- a plant operator can perform any function of the eBATCH system by manual controls in the software or by activating the electromechanical controls found in the junction cabinet.

Yes – with the animated color-based graphical user interface, users become comfortable with using the system after the short training session.

Yes – user authorization is enforced with UserID and password, and data from the system is maintained either on-site or in a network-based storage.

No – there is no limit.